Perfect Spread, Every Time

The Role of Vibrating Table

in Plasterboard Production

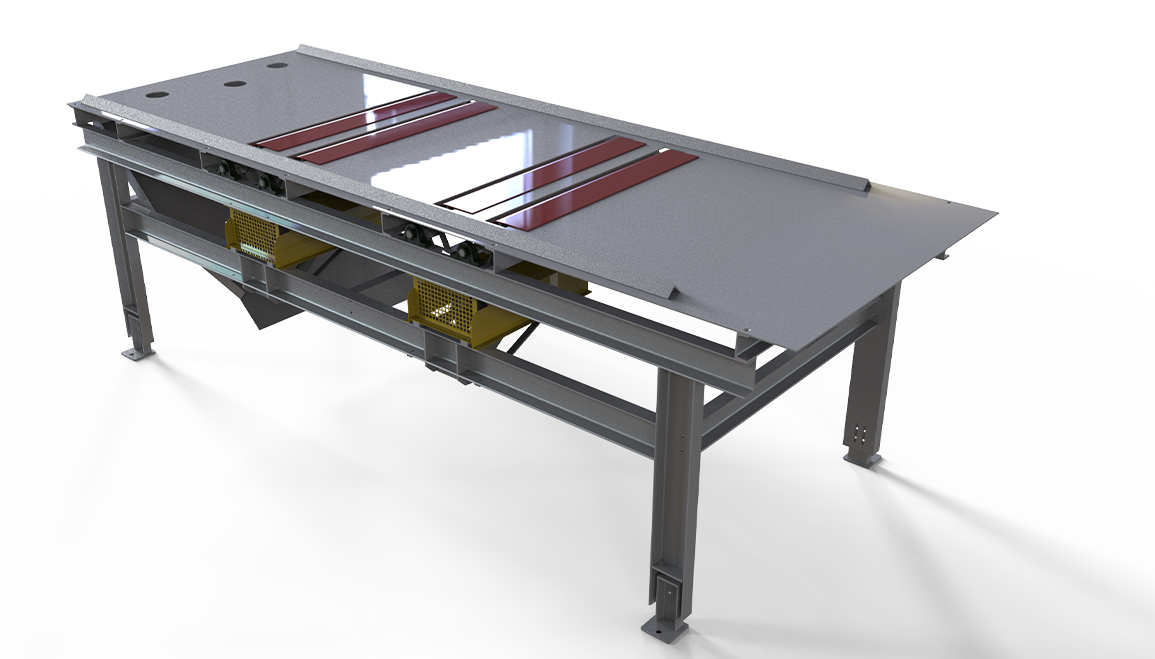

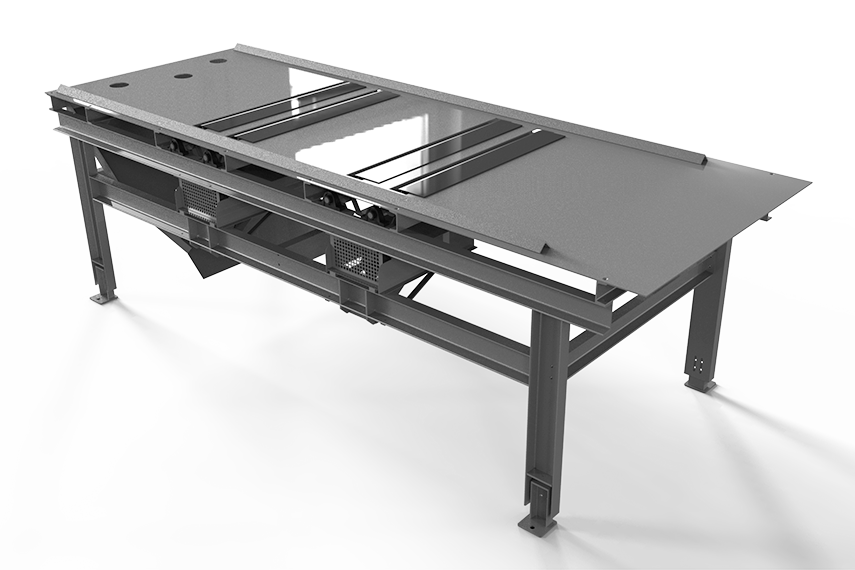

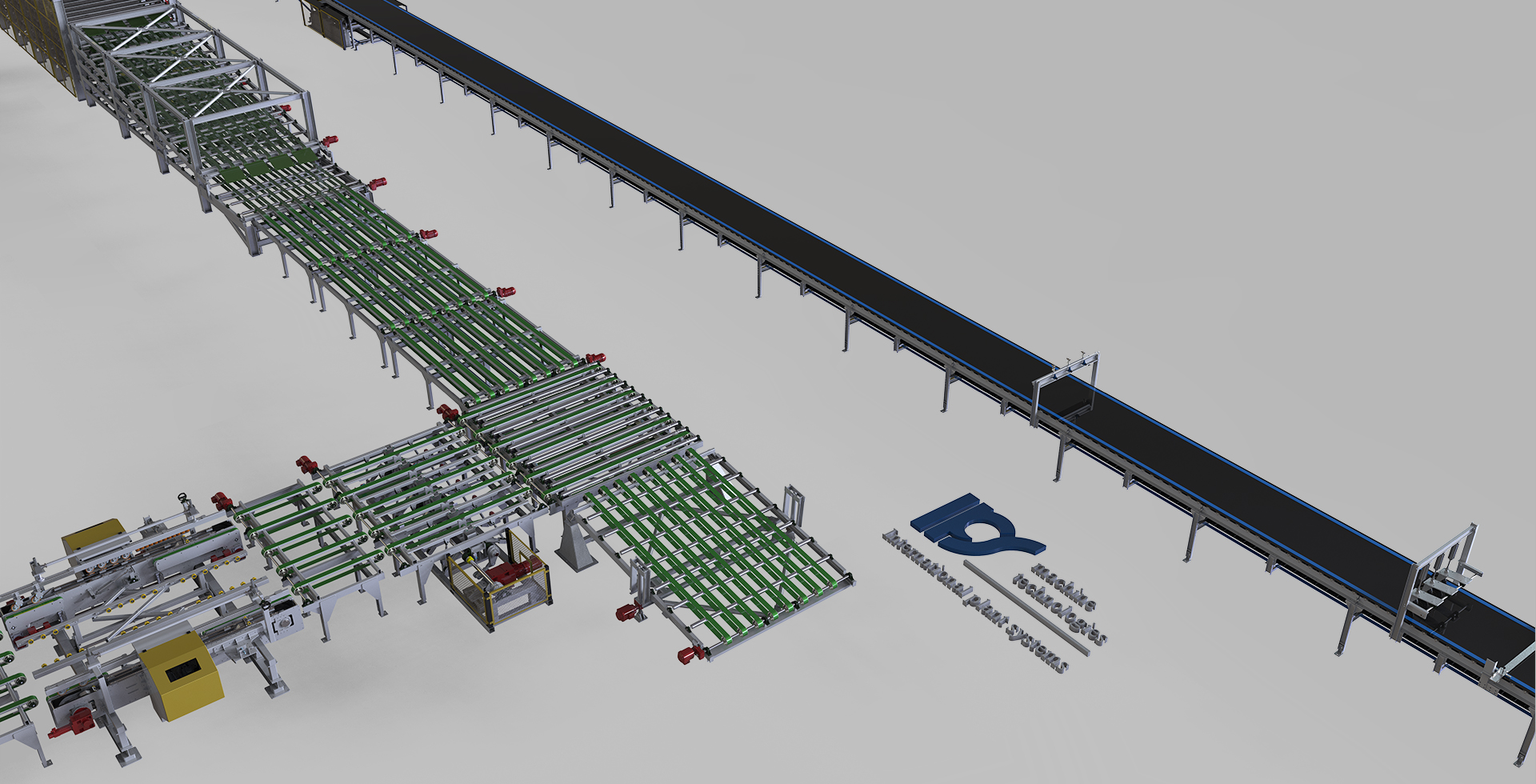

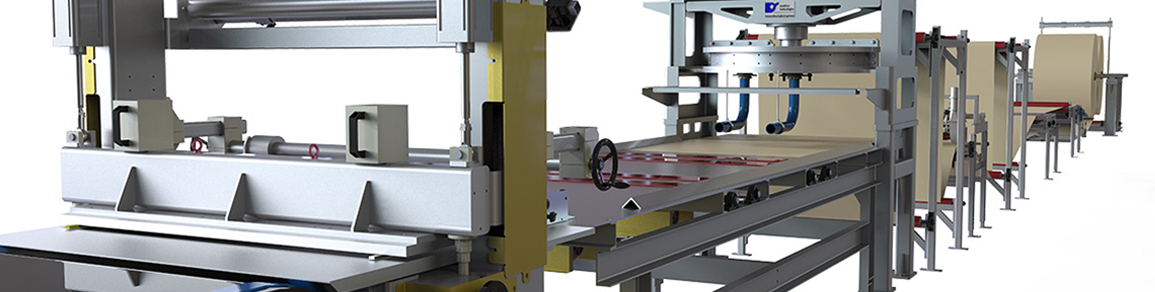

In plasterboard production, precision and consistency are everything — especially in the early stages of board formation. One of the critical yet often overlooked components in this process is the vibrating table. Positioned just after the slurry is poured between the two paper layers on the forming line, the vibrating table plays a vital role in ensuring homogeneity, density control, and surface quality of the board core.

Function and Purpose

The vibrating table applies controlled mechanical vibration to the freshly poured gypsum slurry. This action removes trapped air bubbles, helps the slurry spread uniformly, and improves the bonding between the core and the liner paper. Without proper vibration, the board may develop internal voids, surface imperfections, or poor edge bonding — all of which compromise strength, appearance, and downstream processing.

Technical Considerations

The design of the vibrating table must align with the line speed, board width, slurry viscosity, and formulation type. Vibration frequency and amplitude are precisely calibrated to achieve optimal particle rearrangement without causing surface wave defects or slurry overflow. Over-vibration can lead to edge bleeding and core cracking, while under-vibration can leave voids in the core or uneven paper adhesion.

Advanced systems allow for adjustable vibration zones, frequency control, and automatic synchronization with the main forming belt — especially important when switching between board types or recipe adjustments. Additionally, the table surface material and sealing must be chosen to resist gypsum buildup and moisture exposure, ensuring long operational life with minimal maintenance

Impact on Final Product Quality

A well-functioning vibrating table improves core density uniformity, enhances board strength, and contributes to a smooth, closed surface — all critical parameters for high-quality plasterboards. Especially in high-speed lines or advanced formulations (e.g., fire-resistant or lightweight boards), the performance of the vibrating table directly affects both process efficiency and product consistency.