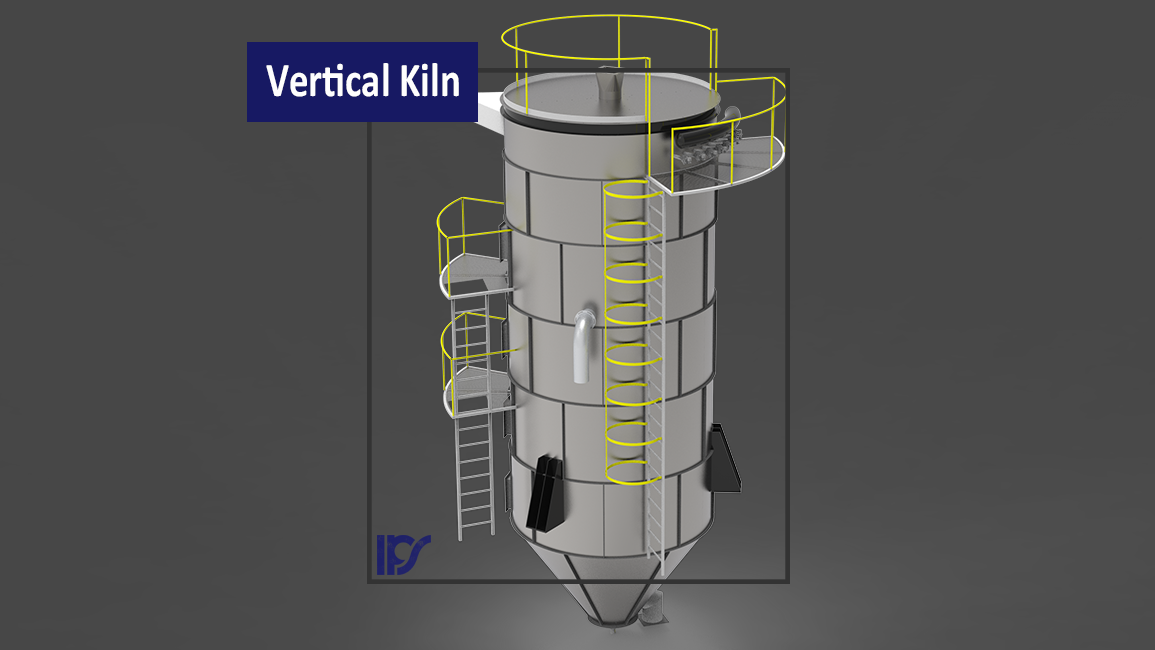

Vertical Kiln for Gypsum Calcination

Compact Design. Maximum Efficiency. Consistent Quality.

The vertical kiln is a precision-engineered thermal processing unit designed to calcine natural gypsum into high-quality hemihydrate (CaSO₄·0.5H₂O), commonly known as stucco. Tailored for gypsum powder production plants with medium to low capacities, the vertical kiln offers an ideal balance between operational efficiency, energy savings, and footprint optimization — making it a highly preferred solution for many manufacturers worldwide.

Engineered for Performance

Our vertical kilns are designed with the specific needs of gypsum plants in mind:

- Optimized Internal Geometry for uniform heat distribution and smooth material flow

- Advanced Combustion Controls to ensure stable flame and precise temperature zones

- Automated Discharge Mechanism to regulate material flow and avoid build-up

- Integrated Dust Management for environmental compliance and clean operation

Every component is selected and configured based on raw material properties, climate conditions, and target production rates to ensure long-term reliability and consistent calcination performance

Why Choose a Vertical Kiln?

- Minimal operational footprint, ideal for tight plant layouts

- Simplified mechanical design with fewer moving parts

- High reliability and low maintenance

- Stable stucco quality, perfect for plaster, mortar, and gypsum board core formulas

Vertical kilns are especially well-suited for producers aiming for cost-effective calcination with stable and predictable performance. Whether for a new installation or as part of a plant upgrade, our vertical kilns offer a future-ready solution engineered for durability, flexibility, and operational excellence.